Braided Hose Has Many Applications

Metal braided hose has been around for many years, and some manufacturers insist it’s the only type of hose that offers the strength and resistance their machinery and applications require.

Many machines and applications called for hoses that were stronger than those made of rubber or canvas, the two typical materials used in the late 1800s. But it wasn’t until a jewelry-maker named Heinrich Witzenmann of Germany and a French engineer named Eugene Levavasseur teamed up in 1885 that anyone had come up with a viable design for this revolutionary type of hose.

The original design came to be called a stripwound hose. It was inspired by a piece of jewelry known to Witzenmann called a goose throat necklace. The necklace consisted of interlaced metal strips. The two inventors took the concept and used it to wrap metal coils around a length of hose. When the hose showed improved strength and resistance qualities and was flexible as well, they continued to develop it as a product for industrial uses.

Stripwound hose and its close relative, corrugated hose, became the only choices for a flexible hose that could withstand the high heat and stress that many manufacturers demanded yet still remain flexible and pliant.

The Evolution of Braided Hose

There were soon requirements for hoses to hold high pressures of air and fluids and remain flexible. Stripwound and corrugated hoses simply were unsuitable for the new application. The spiral edges of the stripwound hose and the multiple corrugations of the corrugated hose were weak points that would often fail under the high-pressure applications they were put through.

The hoses themselves often lost their flexibility and became rigid when subjected to greater pressures. What was needed was a way to make the metal casing as flexible as the hose itself.

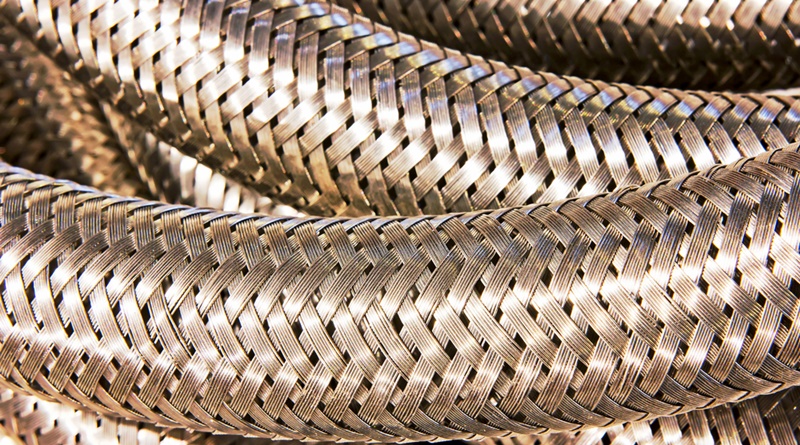

The answer came in the form of braiding that would surround an inner, watertight and airtight hose. By braiding individual threads of metal, an exterior hose could be created which was strong enough to keep the hose within from increasing in size when it was under high pressure. The newly designed hose also maintained its flexibility. It was an instant success and enabled many advances in motors and machines that used high-pressure hydraulics and pneumatics.

Further Advancements

With the further advancements in plastics, many manufacturers found that PVC was a stronger and more practical material to make hoses from. As the hose manufacturing process was basically an extrusion process that used liquified PVC, the metal braiding could be embedded in the hose during the manufacturing process.

The resulting product was just as strong as an exterior braided hose and much less prone to exterior threads breaking from rubbing up against other machinery parts or catching on the parts. Today, PVC hosing is necessary for various fluid, gas, and food and liquid product manufacturing. The braided parts of the hoses guarantee their safety under pressure and increase their endurance.

In Malaysia, Simlecco manufactures and sells a variety of sizes of PVC braided hose that are suitable for all applications. Contact Simlecco to learn more their range of industrial products.